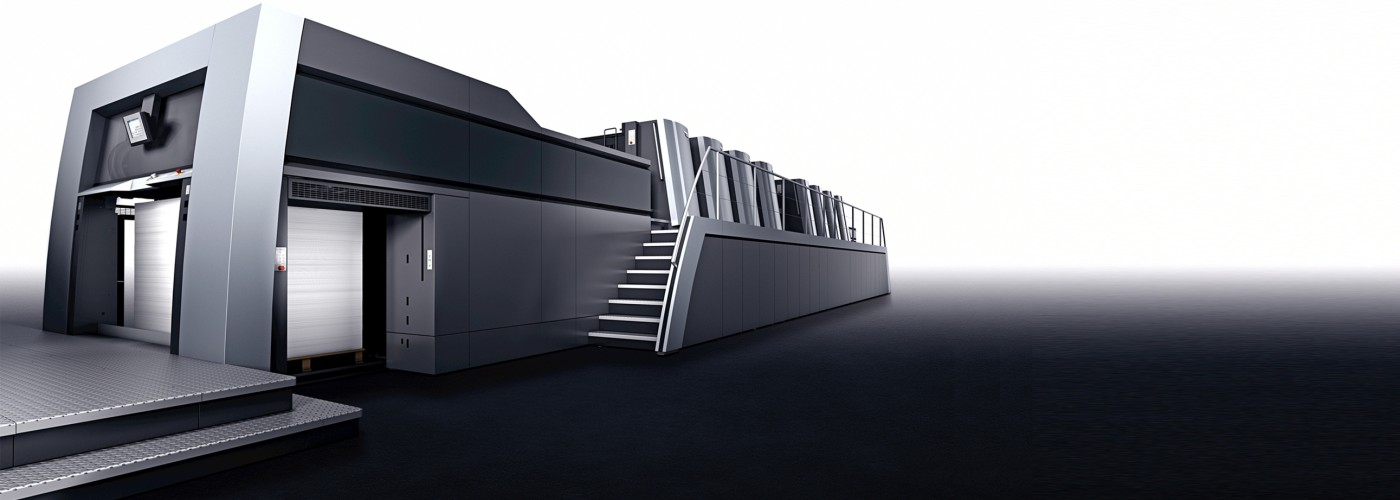

Speedmaster XL 145 and Speedmaster XL 162

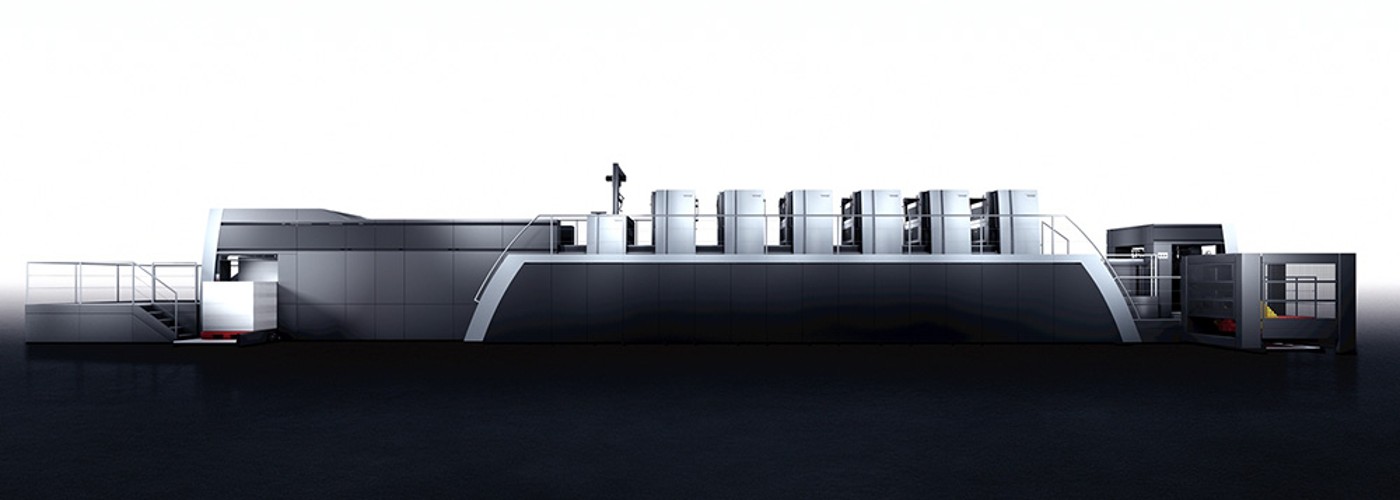

1. User-friendly control of all functions at the Prinect Press Center with wallscreen

2. Fully automated adjustment of the entire Preset Plus Feeder

3. Prinect Inpress Control 2 inline color and register control system

4. Fully automated plate changer AutoPlate XL for complete plate changes in just two minutes

5. Fully automatic perfecting device with variable AirTransfer system and two gripper system for sheet transport at the front and the rear edges of the sheet

6. Transfer of all preset values from the Prinect Press Center to the delivery and automatic positioning of all sheet guidance elements

7. Logistics system with fully automated pile changes in the feeder and delivery

– Peak Performance Class – Technology and Productivity that Know no Compromise

From feeder to delivery, both presses deliver outstanding productivity and cost efficiency with sophisticated solutions that simplify operation, speed up processes, and enhance print quality. The Speedmaster XL 145 and Speedmaster XL 162 offer a whole host of possible configurations, for example equipped with the highly successful fully automatic three-drum perfecting device and the unique double gripper delivery, especially interested for publishing and commercial printers.

Their high energy and resource efficiency make these presses the most environmentally friendly machines in their class. A measuring device can be used to measure the presses’ energy efficiency per 1,000 sheets during production and display this information on the wallscreen of the Prinect Press Center. This allows the operator to run the machines with exceptional energy-efficiency values.

The Star System peripherals are perfectly coordinated with the presses. They are highly efficient and designed to save energy and resources. Reducing or completely eliminating the use of alcohol by equipping the presses with special packages makes another important contribution to ensuring environmentally friendly print production. This results in a print process that delivers eco-friendly operation at low costs.

LEAVE A REPLY