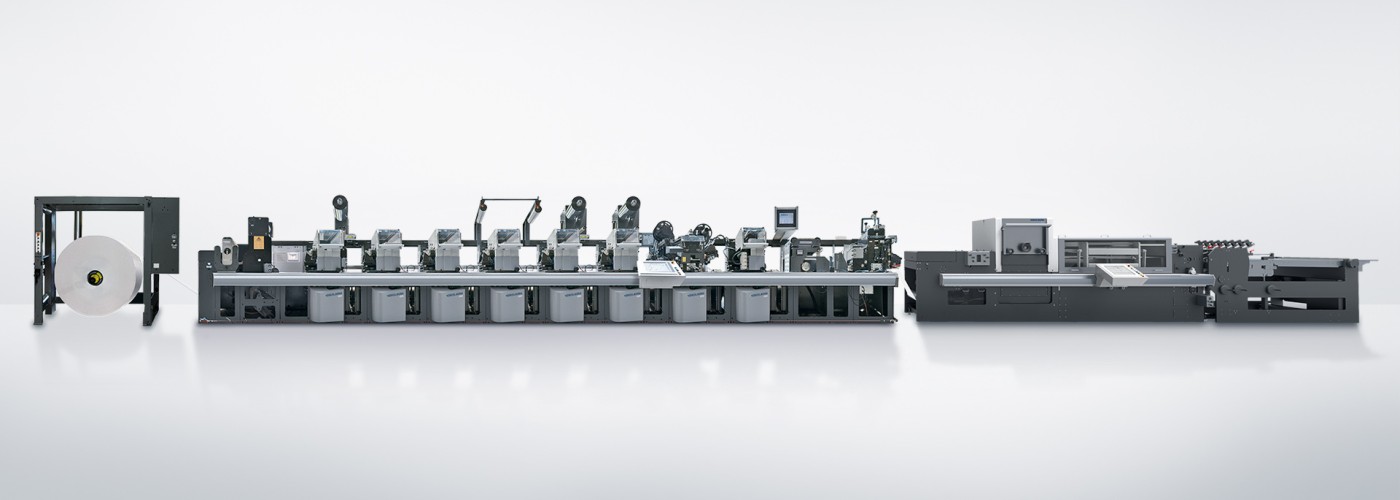

Heidelberg Compact Converting System.

CCS 510 The web-fed press for maximum flexibility in carton converting –

perfect for small to medium order quantities and print formats

A simple workflow is the key to cost-effective production and highest value:

Let the Heidelberg CCS 510 narrow-web folding carton system open up completely new perspectives.

Small and medium run lengths can be produced economically with minimal waste. Thanks to fast changes of colour, tool or whole process, you can use the Heidelberg CCS 510 to produce folding boxes in a single operation from roll to die-cut, gluer-ready blanks.

- Do you want to differentiate from your competition through a variety of flexible value-adding processes and offer your customers a broad portfolio of printed products?

- Do you need a machine that is specifically designed for small to medium run lengths?

- Are you are searching for a single printing system which allows you to cover all these requirements?

If you answered “yes” to any of these questions, the Heidelberg CCS 510 is the right solution.

The CCS is designed especially for the production of:

- Food packaging, sanitary packaging, pharmaceutical packaging and for challenging blisters and blister packs and cups.

- Any job-mix of products with varying levels of finishing requirements.

Maximum efficiency thanks to short changeover times

The Heidelberg CCS is excellent for challenging folding boxes, blister cards and cups. It provides you the short setup and changeover times that are critical to reach highest efficiency for short and medium-length runs. This is achieved through the use of servo-controlled drive technology as well as user-friendly sleeve systems. In addition, low makeready waste from the short web path enhances the economic viability of the CCS.

Maximum process flexibility through modular machine concept

The platform concept of the Heidelberg CCS 510 enables an order-oriented machine configuration. Flexible plug-in modules for screen printing, hot foil embossing, cold foil stamping and lamination allow you to selectively apply different finishing processes, increasing the attractiveness and security of your printed products at the same time.

Effective finishing – cost efficient and economical

Whether screen printing, laminating, hot foil or cold foil application, backside printing or rotary window punching within the printing range, outer contour punching with the flatbed die-cutter Heidelberg FSM – your Heidelberg CCS is well equipped for all these finishing processes. Depending on the print request, tactile or metallic effects, braille and much more can be applied; as well, metallised or transparent films can be laminated – absolutely cost efficient and economical.

All ink systems possible

For both waterbased and UV inks, a Heidelberg CCS is always especially made to your requirements. Within the Heidelberg CCS we can install one or both ink systems in combination to meet your individual challenges.

Simple handling

It’s simple to operate – thanks to easy accessibility, sleeve technology and a dynamic pressure adjustment that automatically adjusts to different printing speeds, the Heidelberg CCS is exceedingly intuitive.

It‘s Inline – Optimal combination creates ideal workflows and accelerates processes

With our integrated solution – printing and finishing in a single pass – we create one simple workflow within your print shop. Whether with integrated flat-bed die-cutting solution Heidelberg FSM 510, unwinder, rotary die-cutter or sheeter – we always configure your machine exactly to your needs. Roll to finished blank – that’s simplicity!

Perfectly equipped for industry and customer requirements – today and tomorrow

Due to the modularity of its design, the CCS web press can be perfectly adapted to your specific challenges. The open interface architecture of the Heidelberg CCS enables this integration and retrofitting to the latest technologies on up to 12 printing or finishing platforms – today as well as later during operation. Get professional in folding cartons or develop yourself as a high-performance flexible packaging provider.

LEAVE A REPLY