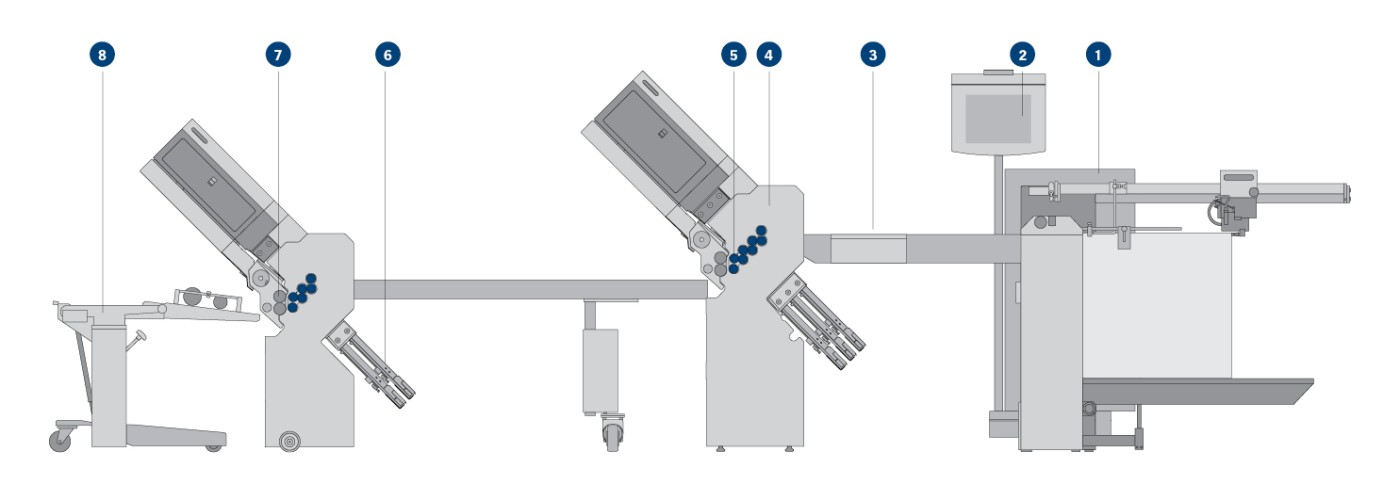

EFFICIENCY. STAHLFOLDER BH/CH.

Our tried and tested Stahlfolder BH/CH folding machines offer all the benefits you would expect of Heidelberg: high reliability, stable productivity, and dependable folding quality. The compact design and the automation options require only a minimum of settings. This makes it easier for you to get started with professional folding and brings your folding up to state-of-the-art standards.

The Stahlfolder BH buckle plate machines and Stahlfolder CH combination folding machines will reduce your throughput times, enabling you to respond flexibly to order peaks. This means that you can accommodate additional capacity for producing high-quality folded products at any time, should you need it. The low volume means that your investment will pay itself off within the shortest time, even with one-shift operation.

So no matter whether your focus is professional quality and fast turnaround times, consistently high output, or modernizing your postpress setup, the technology of the Stahlfolder BH/CH folding machines will always deliver good results. Their ease of operation makes them suitable for producing a wide range of signatures for producing books or commercial products like flyers. Build on a reliable partnership for your postpress needs and count on the special qualities of Heidelberg with the Stahlfolder BH/CH folding machines.

Feeder (1)

Three feeder variants available – adapted to different demands

With flat pile feeder, round continuous feeder and pallet feeder, the Stahlfolder BH/CH folding machines offer the required feeding system for every demand.

Flat pile feeder

The flat pile feeder is designed for frequently changing fold jobs with small to medium run lengths. It ensures a perfect sheet separation and is easy to operate. Further advantages are the little space requirements and the low investment costs. The preloading device allows the operator to prepare follow-up jobs already while the current job is running. For this purpose further mobile pile tables, which only need to be exchanged during the set-up, can be loaded on the folder or already on the cutting machine. This minimizes unproductive downtimes.

Round continuous feeder

The round continuous feeders process different kinds of paper in non-stop operation in medium to large runs – wavy sheets and pre-folded, -perforated or -punched products are laid onto an especially long loading table in shingled way. Due to this non-stop feeding the daily production is approx. 20% higher compared to the flat pile feeder. The ergonomic loading height of 94 centimeters is pleasant for the operator and supports a quick loading.

Pallet feeder

The pallet feeder is the feeder with the lowest expenditure for the operator. Sheets do not need to be pre-piled – in fact the pallet can pull from the delivery of the press directly into the feeder of the folding machine. This reduces the setup time which allows the operator to fully concentrate on the folding and unloading of the sheets. This way the performance of the folding machine can be fully used in one-man-operation. The maximum pallet height of 1.20 meters is ideally matched to the delivery height of a typical sheet-fed printing press.

Feeder details:

- Sheet separation device Tremat: provides ventilation and pre-separation of the sheets in flat or pallet feeder by means of continuously adjustable blowers at the trailing sheet edge. The Tremat ensures a stable and high productivity of the folding machine with clearly reduced setup time.

- Sheet acceleration with suction wheel: A polyurethane-coated suction wheel ensures that the sheets are separated quickly and without markings, accelerated reliably and conveyed onto the register table.

- Optional feeder automation: All thickness-relevant settings for folding rollers and slitter shafts are automatically adjusted to the job-specific values.

Modular control system MCT (2)

Modular control system MCT for easy operation of your folding machine

The graphical user interface makes the operation easy. With Touchscreen and QuickSetup all necessary settings are done with just four clicks.

The MCT control system consists of a central control panel at the feeder of the folding machine and integrated control functions, both in the following units as well as in the delivery which offer complete control over the most important machine functions. In the learning mode the sheet length is measured and the suction cycle length and sheet gap are automatically set and continuously monitored.

LEAVE A REPLY