Heidelberg offering innovative solutions for greater productivity and user-friendliness in postpress

delivery, a novelty in this format class.

Download image in high-resolution

The various finishing processes still offer a lot of potential with regard to greater automation, higher productivity, and integrated processes. These are issues that need to be addressed by both commercial and packaging printers. Add to this the requirement for simpler and more user-friendly machines for compensating the skills shortage and reducing the level of physical work. Heidelberger Druckmaschinen AG (Heidelberg) has listened to its customers and developed appropriate new solutions.

“In commercial printing, the postpress department accounts for the highest personnel costs at typically around 60 percent,” explains Jörg Dähnhardt, Head of Postpress Business Management at Heidelberg. “That’s why we’ve put the focus here on integrated automation, like for instance with Push to Stop technology for the folding machines, in order to reduce makeready times and increase productivity. Likewise with the Stahlfolder P-Stacker robotic system, we increase the flow of materials and reduce the operator’s workload.”

“In commercial printing, the postpress department accounts for the highest personnel costs at typically around 60 percent,” explains Jörg Dähnhardt, Head of Postpress Business Management at Heidelberg. “That’s why we’ve put the focus here on integrated automation, like for instance with Push to Stop technology for the folding machines, in order to reduce makeready times and increase productivity. Likewise with the Stahlfolder P-Stacker robotic system, we increase the flow of materials and reduce the operator’s workload.”

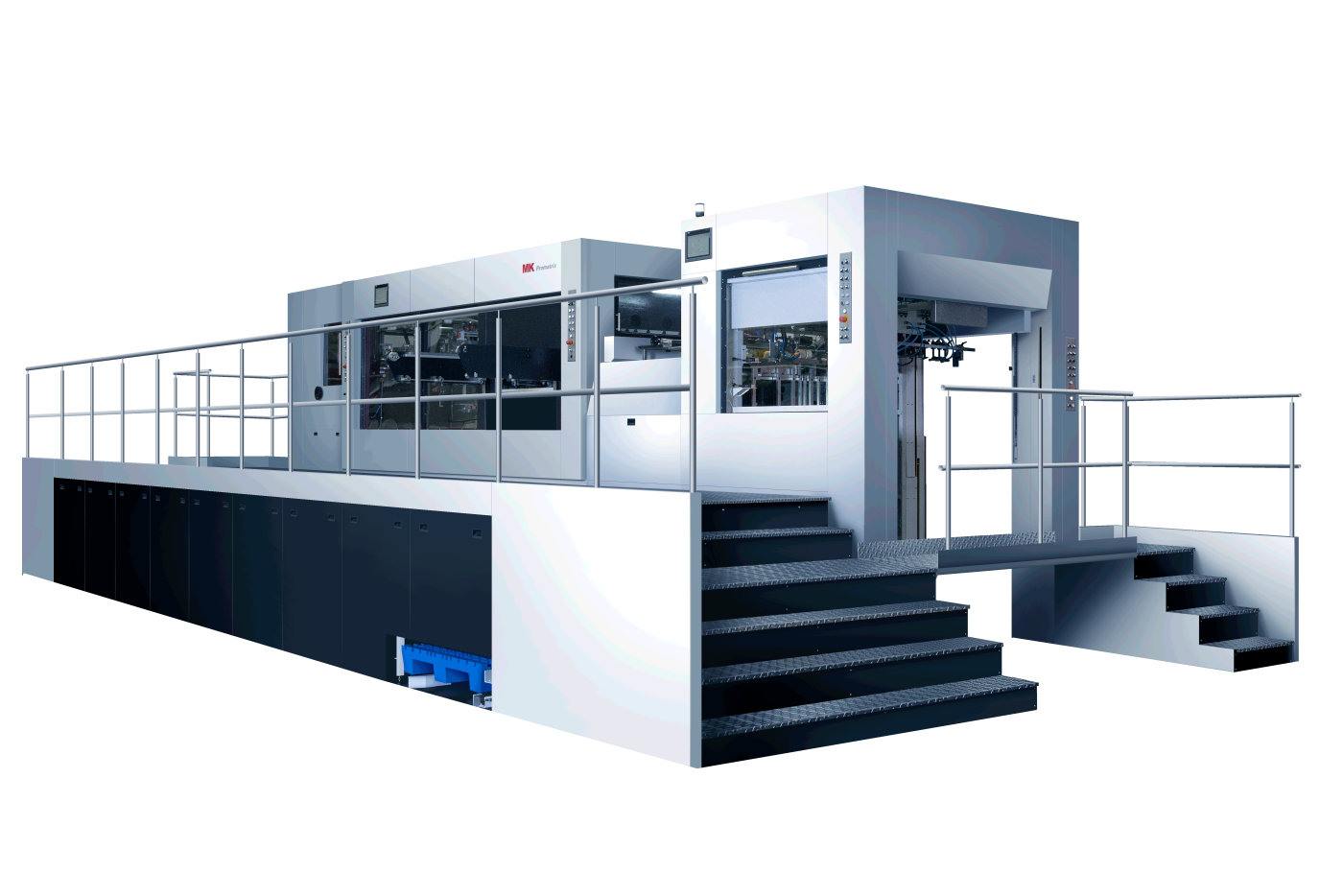

The packaging area continues to grow, and with it the market’s requirements. On the one hand it is about smooth production of longer runs, on the other hand run lengths are declining, the number of jobs is rising, and everyone is talking about sustainability. This prompted Heidelberg to round out its die-cutting portfolio both upwards in higher performance ranges as well as downwards, in order to offer a solution for every application. The Powermatrix 106 CSB and Promatrix 145 CSB die-cutters will be new launches. For short runs from digital and commercial printing comes the new Multimatrix 60 FC, which offers an attractive price/performance ratio and is therefore suitable for smaller printing companies. It offers significantly higher productivity than the Heidelberg windmill and cylinder presses still used. “We’ve diversified and extended our range of die-cutters and folder gluers and can now also mirror the productivity of our printing presses. In order to be able to keep up with the higher speeds of the Diana Smart, we’re using a loading robot for the first time. The Diana Packer 4.0, which can pack up to 200,000 cartons per hour, can handle the speed at the delivery,” confirms Dähnhardt.

In general in postpress there are machines from a wide range of manufacturers and – at least in the commercial sector – still lots of manual and time-intensive steps that make a post calculation almost impossible. The new Heidelberg standard interface Postpress Data Ready ensures transparency and efficient order processing here. Postpress Data Ready concentrates purely on the acquisition of operating data, whether from the commercial or packaging area. The largely automated data acquisition refers, for example, to real-time data on production progress. As a result, the customer receives a reliable data basis for more efficient capacity planning and for easier final costing. Postpress Data Ready is a non-proprietary data interface and can thus be integrated into existing MIS systems. Data Ready is immediately available for the Diana folder gluers, for the die cutters and folders the interface will be introduced at a later date.

Originally Published: Heidelberg Global